High-Pressure Metering Systems for Polyurethane Processing Equipment

Linden Polyurethane is proud to offer best-in-class high-pressure polyurethane processing equipment. Our high-pressure metering systems provide immense flexibility to support your polyurethane processing and dispensing needs. With two specific models available that serve as the foundation for customization as well as a host of ancillary and support options and upgrades, our high-pressure metering systems have become the polyurethane processing equipment of choice for organizations that expect uncompromising top-of-the-line performance, accuracy, and reliability in their polyurethane production environment.

Polyurethane is a critical component of many industries and impacts the performance of multiple products in consumer, business, and government applications. Every day, our metering systems are put to the test in these applications — and only the best pass. That’s because in many industries, it’s about more than just performance and accuracy — it’s about protecting people, ensuring safety, and promoting health and wellness. That’s why we customize all of our polyurethane processing equipment to help our clients meet these strict demands.

Available High-Pressure Metering Systems

Linden offers two distinct high-pressure metering systems for polyurethane processing equipment: the extremely powerful and customizable INNOVATOR™EP and the highly accurate and controllable Linden-Isotherm PSM 90.

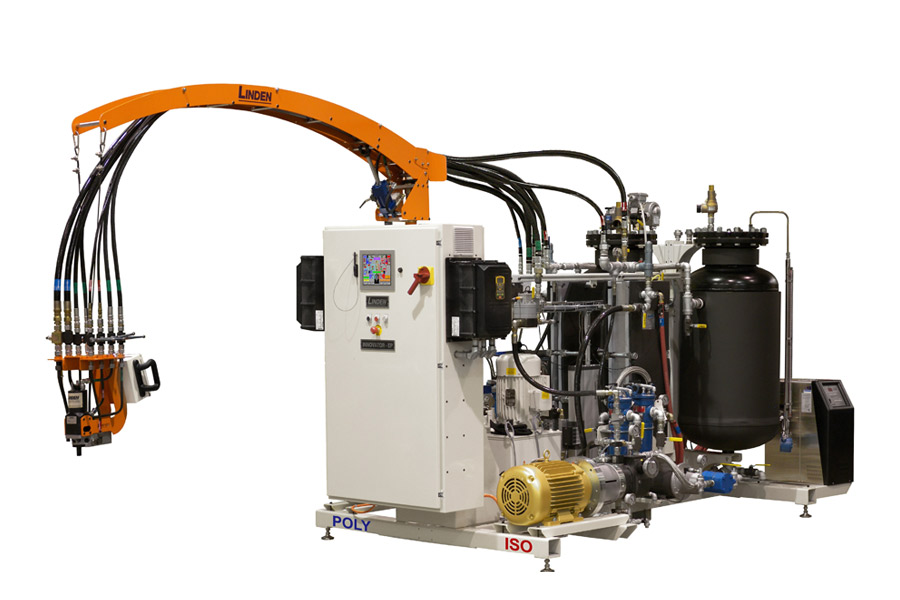

INNOVATOR EP

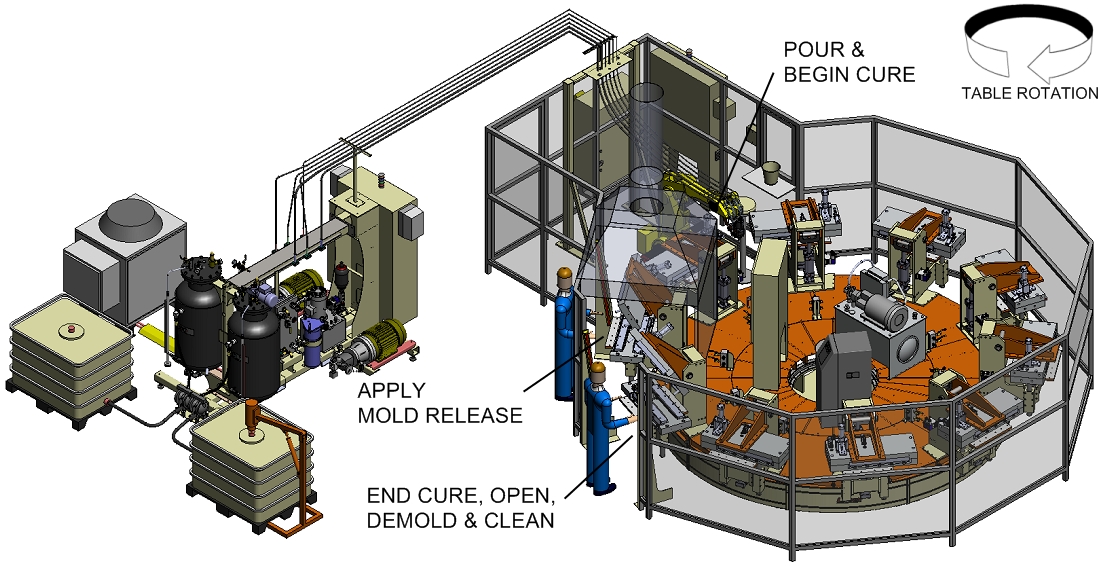

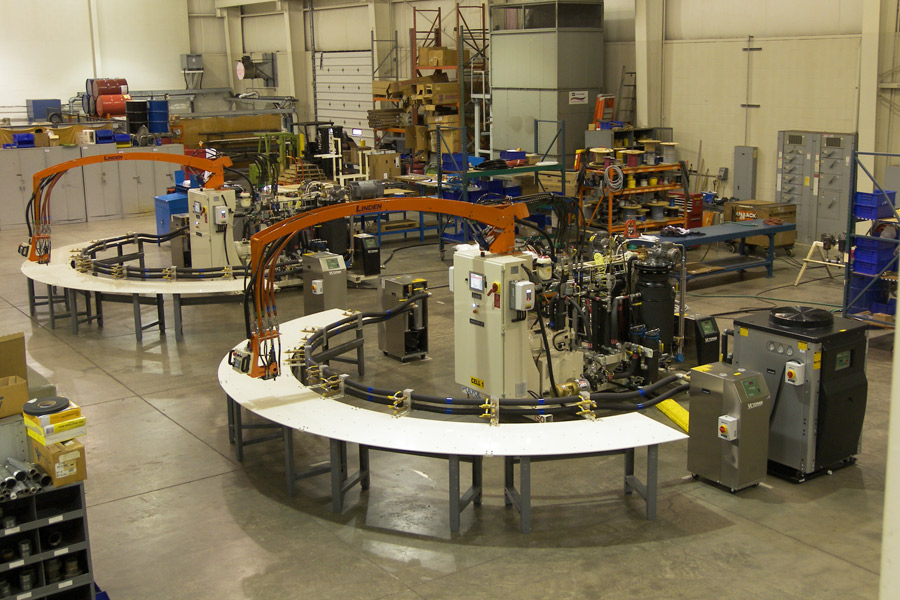

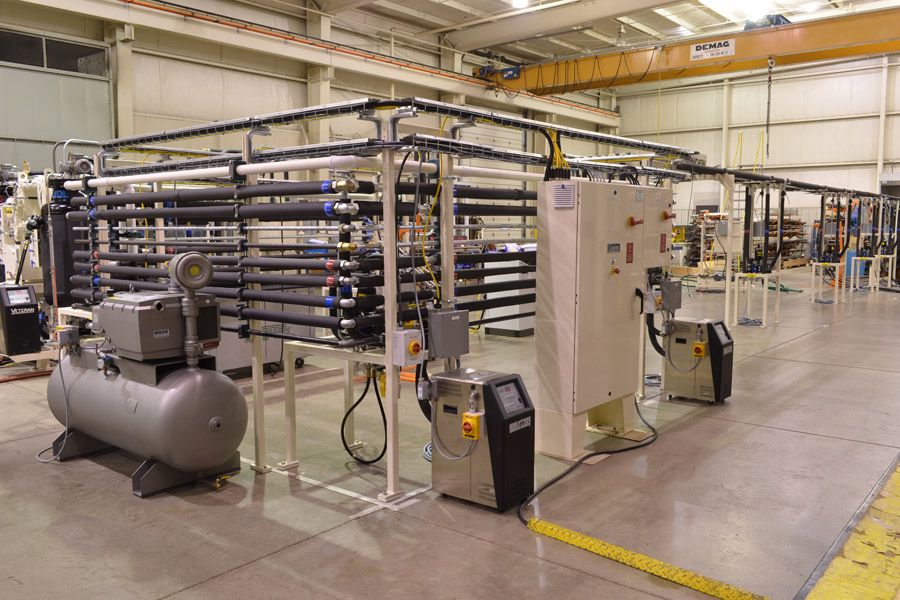

As the building block of our polyurethane processing equipment and high-pressure metering capabilities, the INNOVATOR EP provides extensive customization to meet your specific application demands. From use in a basic two-stream metering application to being fully integrated into a production cell, the INNOVATOR EP allows users to adapt their chemical formulation and plant footprint to achieve specific goals. The INNOVATOR EP is also available with a Penta-Meter ancillary metering unit that replaces HCFs and HCFCs with Cyclo-Pentane or HFO blended into the polyol near the mix head for more environmentally responsible processing.

INNOVATOR EP Highlights

- The most advanced American-made polyurethane machine on the market

- Modular block building design allows for extensive customization

- Output of 4.6 lb/min (0.9 kg/min) to 825 lb/min (680 kg/min) at ratios from 1:5 to 5:1

- Can be integrated with robots, turntables (small/large), or conveyors

- Can become part of a continuous process line

- Environmentally responsible, energy efficient, and operator friendly

- Extensive standard features and numerous optional upgrades and features

- Supported by a best-in-class warranty and repair program

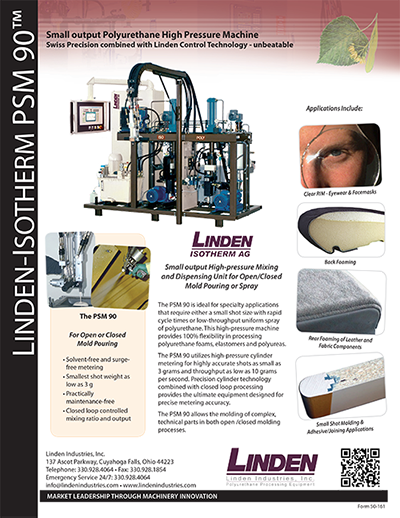

Linden-Isotherm PSM 90

If your application demands polyurethane processing equipment that can produce small-output open/closed mold pourings or spray, the Linden-Isotherm PSM 90 is the high-pressure metering system for you. Designed specifically for the molding of more complex and technical parts, the PSM 90 delivers small shot sizes with rapid cycle times as well as low-throughput uniform spray — ensuring the utmost in flexibility, precision, and reliability.

Isotherm PSM 90 Highlights

- Ideal for rigid, flexible, or integral skin foam parts as well as RIM or RRIM systems

- Shot weights as low as 3g and throughput as low as 10g/sec at ratios from 1:4 to 4:1

- Solvent-free and surge-free metering that requires little to no maintenance

- Utilizes closed loop controlled mixing ratio and output for ultimate precision

- Supported by a best-in-class warranty and repair program

Our Partnership with Isotherm AG

For more than 35 years, Isotherm AG has developed, and delivered high-pressure PUR-installations for very different spraying and molding applications in Europe and overseas. Utilizing their in-depth knowledge of the polyurethane spray applications and small shot sizes has allowed Linden customers to benefit from this partnership by integrating the solutions and the operational reliability. Learn more about our partnerships here.

Linden Mix Heads & Quality Craft Machine Mix Heads

Both the INNOVATOR EP and Isotherm PSM 90 high-pressure metering systems allow for multiple mix heads to be connected based on the application need. To ensure your production environment utilizes only the most advanced and reliable mix heads, Linden Polyurethane offers our custom-designed and engineered mix heads along with Quality Craft Machine mix heads.

Get Best-in-Class Support for Your Polyurethane Processing Equipment

Whether for a high-pressure metering system or a mix head, Linden Polyurethane is your best choice for fast, efficient, and cost-effective repairs and parts replacement. We provide support for our own brand of equipment and mix heads as well as those from other manufacturers. And because we’re U.S.-based, we can work closely and quickly with you on your repair or part replacement. Our remote monitoring and diagnostics service allows us to tap into your production environment to identify issues and provide recommendations. Learn more about our repair and parts services here.

Ready to Get Started?

Contact us to learn more about our high-pressure polyurethane foam machine options and to request a quote.

| Machine Size | EP2 | EP6 | EP 11 | EP12 | EP 28 | EP33 | EP55 | EP 62 |

|---|---|---|---|---|---|---|---|---|

| Pump Manufacturer | RHL | RHL | RHL | Rexroth | Rexroth | RHL | Rexroth | RHL |

| g/second | 22 - 110 | 66 - 332 | 127 - 636.8 | 128 - 642 | 311 - 1555 | 365 - 1827 | 605 - 3025 | 687 - 3433 |

| Kg/minute | 1.3 - 6.6 | 4 - 19.9 | 7.6 - 38.2 | 7.7 - 38.5 | 18.6 - 93.3 | 21.9 - 109.6 | 36.3 - 181.5 | 41.2 - 206 |

| lbs/minute | 2.9 - 14.7 | 8.8 - 43.9 | 16.8 - 84.2 | 17 - 84.9 | 41.1 - 205.6 | 48.3 - 241.7 | 80 - 400 | 90.8 – 454 |

Based on 1.0 S.G. (Specific Gravity)

Based on Ratio of 1:1

Ratio range of 3:1 – 1:3

Maximum shot pressure 2800 PSI (197 Bar)