Low-Pressure Polyurethane Machines

Low-pressure polyurethane foam machines support a number of applications in which lower volumes, higher viscosities, or differing levels of viscosity between the various chemicals used in a mixture are required. To that point, low-pressure polyurethane foam machines are also an ideal choice when multiple streams of chemicals need to be treated differently prior to mixture.

Low-pressure polyurethane foam machines are often found in a variety of markets, particularly where C.A.S.E. (coatings, adhesives, sealants, and elastomers) polyurethanes are needed. For example, in the automotive industry, low-pressure polyurethane foam machines are used in vehicle coatings to provide gloss and promote color retention while simultaneously protecting from scratches and corrosion. In the building industry, polyurethane is applied to structural elements like floors, beams, and other supports to protect them from rusting and making them easier to clean. Polyurethanes are also applied via low-pressure in the aerospace industry to protect parts of the aircraft from extreme temperature variations and from rust.

Available Low-Pressure Polyurethane Machines

Through our partnership with Polytec EMC, Linden Polyurethane provides three low-pressure polyurethane foam machines to meet your production needs.

Polytec EMC DG 132

Ideal for small to midsize production needs, the DG 132 is a standardized configuration for 2- or 3-component reactive systems such as TDI, MDI, or MBOCA. Heated component lines allow temperatures of up to 302°F (150°C). Color dosing and a vacuum unit further increase the flexibility of the DG 132 low-pressure polyurethane foam machines.

Highlights

- Output ranging from 100 to 6000 g/min to meet your production needs

- Features an optional third component module for expanded capabilities

- Tank sizes available from 9 to 264 gallons (34 to 1000 liters)

- Also features degassing, a service modem, and volumetric mass flow control

- Automatic refilling ensures continuous material flow

- Supported by a best-in-class warranty and repair program

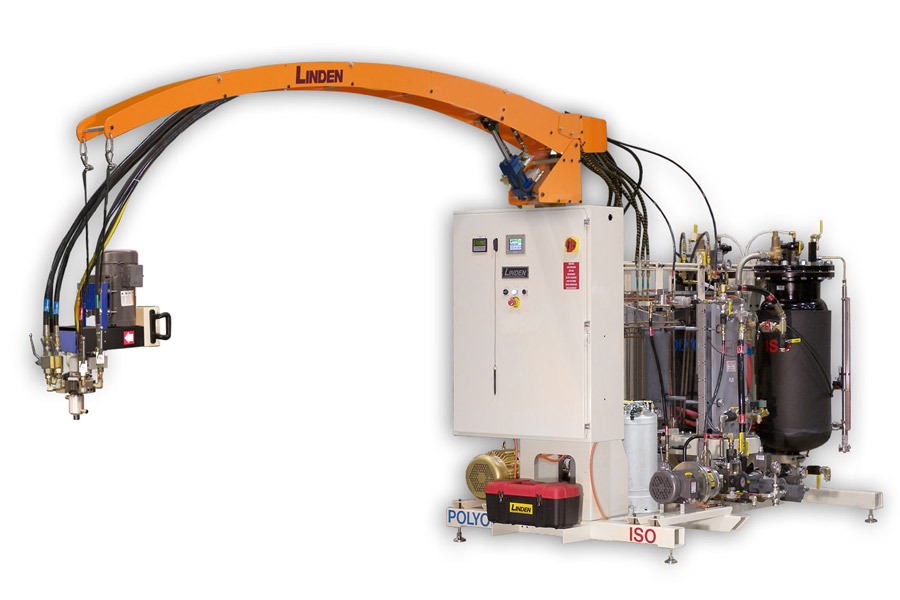

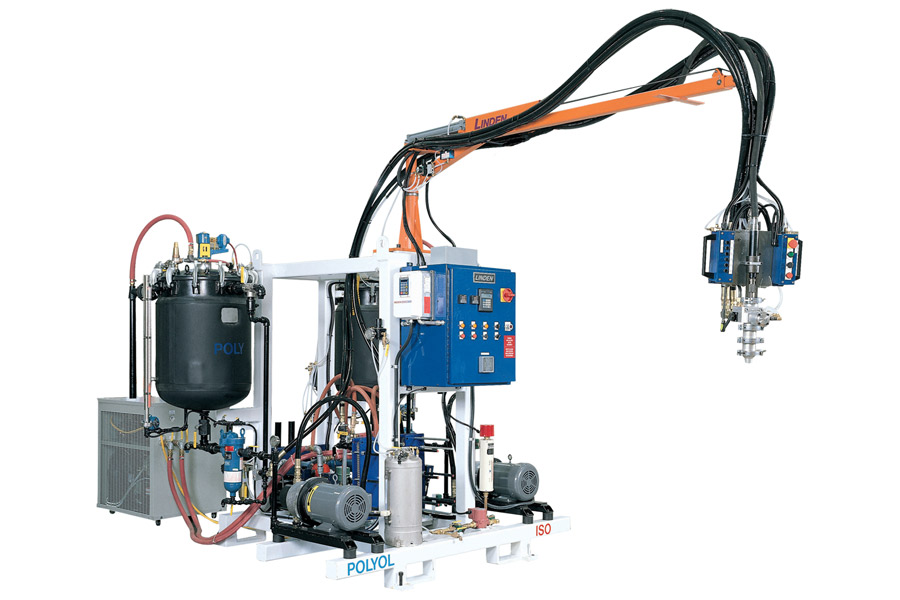

Polytec EMC DG 150

The Polytec DG 150 series of low-pressure polyurethane foam machines is a great midrange solution for 2- and 3- component metering, mixing, and dispensing. The DG 150 is capable of working with all cold- and hot-castable reactive chemicals including PUR, epoxy, cast-nylon, silicones, liquid resins, and more.

Highlights

- State-of-the-art technology and superior control and operation

- Output ranging from 13.2 to 39.6 lb/min (6 to 18 kg/min)

- Efficient energy consumption

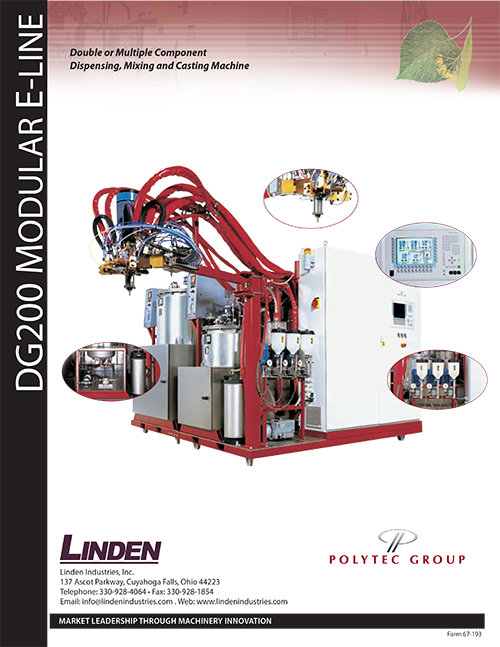

Polytec EMC DG 200

The Polytec EMC DG 200 line of low-pressure polyurethane foam machines can support virtually any application or requirement with a custom-made mixing solution. The DG 200 allows for up to six component lines drawing from larger tank sizes and at higher output rates than other DG series machines. A variety of optional additions ensures this machine can be customized to meet your most demanding polyurethane application needs.

Highlights

- Allows for up to 6 component lines on a modular-based system

- Output rates of up to 26.4 gal/min (100 kg/min)

- Throughputs up to 3.6 gal/sec (100 l/min)

- Tank sizes up to 400 gallons (1500 liters)

- Programmable PLC system with optional process visualization and report logging

- Dosing pumps are available for filled and abrasive systems

- Supported by a best-in-class warranty and repair program

Our Partnership with Polytec EMC

For more than 25 years, Polytec EMC has been recognized as a leading manufacturer of low-pressure polyurethane and cast elastomeric processing machines. They are best known for their quality and design innovations they have incorporated in their machine development and manufacturing. Utilizing their in-depth knowledge of the polyurethane and cast industries has allowed Linden customers to benefit from this partnership by integrating the solutions and the operational reliability of the machines Polytec EMC builds into our core offering. Learn more about our partnerships here.

Ready to Get Started?

Contact us to learn more about our low-pressure polyurethane foam machine options and to request a quote.

Please contact us to discuss specifications for this equipment.