Pentane Machinery

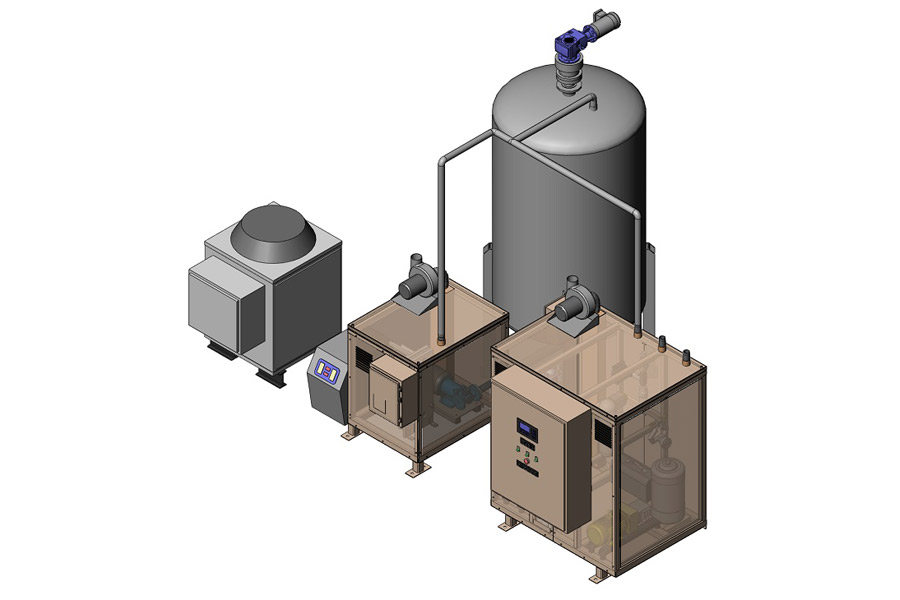

Pentane is an environmentally friendly replacement for outdated blowing agents that have been identified as potentially harmful. Previous blowing agents such as HFCs and HCFCs had a high global warming potential (GWP), resulting regulatory agencies calling for emissions control on them. Linden Polyurethane offers pentane machinery solutions designed to help organizations meet their production demands while also maintaining compliance with local regulations and supporting environmentally safe best practices.

While pentane does offer certain benefits over HFCs such as a lower overall price and higher insulation R values, it does carry some risks. Machines must be altered, as pentane is flammable. To counter this for continuous operations, Linden Polyurethane pentane machinery can blend pentane into the polyol mixture in-line prior to the material reaching the mix head. In specific blending instances that are not continuous, pentane can be blended into the polyol prior to mixing.

Pentane is the preferred blowing agent when the amount of foam that will be used is much higher. For example, pentane will be part of the overall mixture in board or panel lamination. Different subcategories of pentane are also available based on the application. Cyclopentane and ISO pentane are utilized when local regulations are more relaxed. These feature lower thermal conductivity and are often used in consumer white goods such as refrigerators.

Ready to Get Started?

Contact us to learn more about our pentane machinery solutions.

Please contact Linden Polyurethane to learn more about our pentane machinery solutions.

No downloads are available at this time. Please check back later or contact us.