Production Success Requires a Properly Functioning Mix Head

Numerous Industries around the world rely on their mix heads for efficient, ongoing production. Many products and materials require polyurethane as a key ingredient in their design and construction. When a mix head cannot accurately or reliably combine and dispense the right chemical mixture, the quality of the end product is impacted, or cannot be made. The specific production line that a particular mix head supports stops, and the production chain as a whole is impacted. When a mix head goes down, efficient mix head repair is absolutely essential.

Another area in which accurate mixtures are an unwavering necessity is in military applications. Whether for insulation and noise reduction in shipbuilding or temperature protection and exterior coatings for aircraft, being able to efficiently mix the chemicals with precision and achieve continuous throughput from machine to surface is important. When mix head repair is required, speed and precision are essential in order to ensure production deadlines are met.

Finally, in the automotive industry, a mix head’s ability to continuously combine material accurately and ultimately dispense it based on the application is key to the entire vehicle production line. While there will undoubtedly be a number of mix heads in a production chain, when it comes to one that’s not operating properly, is no longer able to keep itself clean, or cannot function properly and achieve a precise mixture, the production challenges can be significant and expensive.

Understanding the Available Mix Head Repair Options

When you’re in need of repair, time is of the essence. Whether your facility has one mix head combining material or a full line of polyurethane machinery and mix heads operating around the clock, timelines and production goals must be met. At Linden Polyurethane, we provide our clients with a number of options for mix head repair based on their needs.

Repair or Rebuild

Whether your mix head was damaged, is exhibiting signs of wear and tear, or has problems with its inner workings, you have options. A standard repair will identify the problem and resolve it. Expert repairmen with years of industry experience will disassemble the mix head and troubleshoot it in order to find the problem and fix it. If needed, the option to rebuild the mix head will be presented. This mix head repair solution returns an existing piece of equipment back to peak operational performance without needing to purchase an entirely new mix head.

Parts Replacement

Over time, key components of your mix head will wear down, require cleaning, or potentially get damaged. In this instance, only those key parts need to be replaced. Once you send in your mix head for repair, our technicians will identify the part needing replacement. Our industry-renowned warranty may cover your part replacement, though many of our mix heads are built to such high standards that they often outlast even our warranties! With your mix head repaired, it can be added back into your production process.

Mix Head Rental

If your mix head is too badly damaged, or an extensive rebuild is needed, we also offer mix head rentals. When you send in a mix head for repair, we’ll ship a temporary replacement out to you right away so you can maintain your production efficiency. Once your mix head has been repaired, we’ll ship it back to you. When swapped out, the rented mix head is shipped back to Linden Polyurethane per our rental agreement.

Be Proactive with Your Mix Head Repair Needs

Mix head repair is a time-sensitive effort, which is why it’s important to take immediate action. If your organization is in need of assistance, contact us as soon as possible. We’ll help you determine the best course of action. We are also proud to provide repair services for equipment manufactured by other industry organizations apart from our own. These include Cannon, Hennecke, Krauss Maffei (KM), and Elastogram (EMB).

While no mix head is free from wear and tear or the occasional mishap, Linden Polyurethane takes great pride in offering the best warranties in the industry as well as custom-engineering advanced mix heads from the start. Often, our mix heads are sent back to us for repair, only for us to find that the mix head has completed more than one million shot cycles on its counter — an unprecedented number of shots!

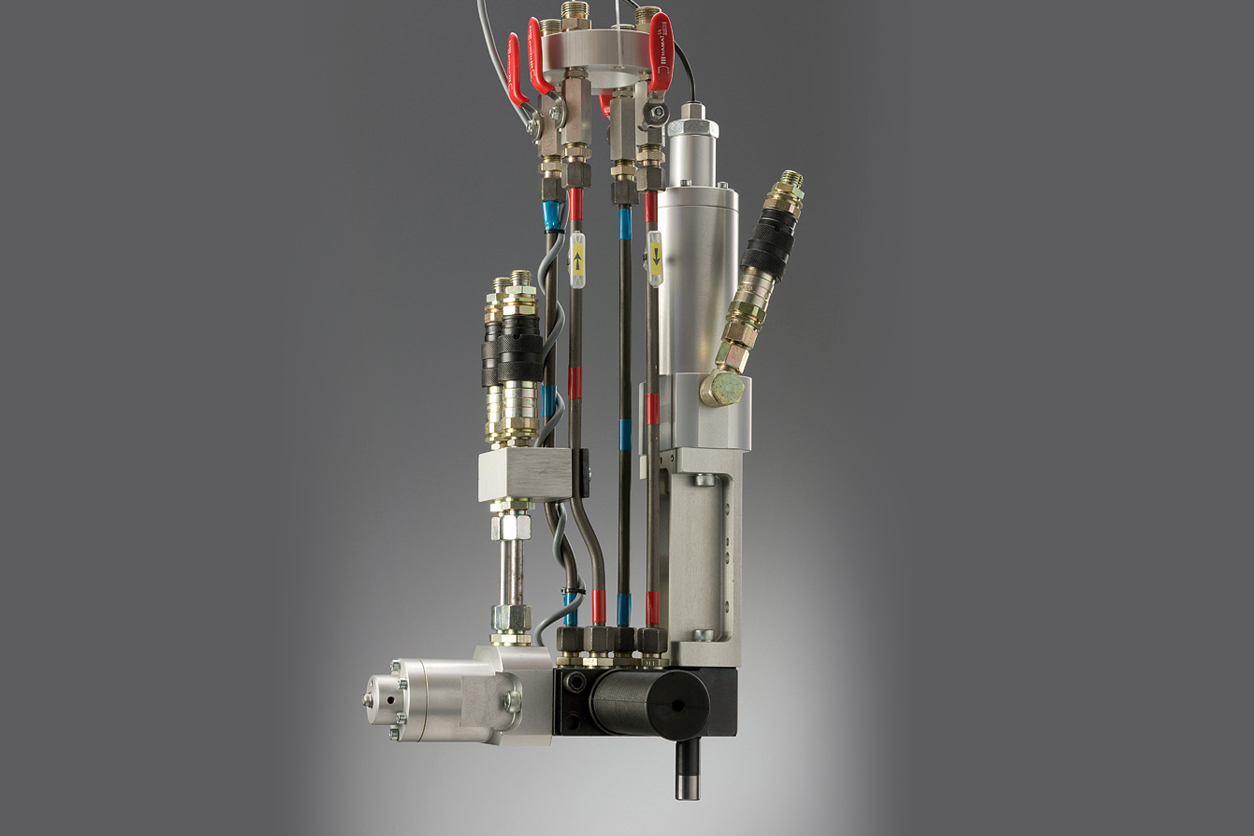

We are a world-class provider of many different styles of mix heads, ranging from L-style mix heads with advanced mixing and laminar flow capabilities to straight- and spray-style mix heads for smaller, more complex molds and difficult-to-reach areas. Whatever your mix head needs may be, we’ll work with you to engineer the ideal solution while also remaining available to support your mix head in the future.

Contact us today to learn more about our mix head repair and design capabilities.