26

Jun 24How Polyurethane Roofing Enhances Energy Efficiency

- June 26, 2024

Save Money by Investing in Polyurethane Roofing

Polyurethane roofing — particularly spray polyurethane foam (SPF) — was popularized in the late 1970s as an energy-efficient solution for roofing applications. Over the decades, it’s proven to be a game-changer for both commercial and residential buildings.

Read more

31

May 24Exploring the Benefits of SPF Insulation

- May 31, 2024

Is SPF Insulation Right for Your Project?

When it comes to building residential and commercial structures, there are a lot of decisions to make. Among them is the type of insulation you’ll use.

Read more

27

Mar 24Closed-Cell Spray Foam: What is it and is it Right for You?

- March 27, 2024

Should You Use Closed-Cell Spray Foam for Your Application?

In both commercial and residential building projects, you must choose what kind of insulation you want to use. There are a variety of options out there, one of the most popular being closed-cell spray foam. But, how do you know what’s right for you? In this blog, we’re diving into the closed-cell option and comparing it with other popular insulation materials, like fiberglass, cellulose, and open-cell spray foam. Let’s get started.

Read more

18

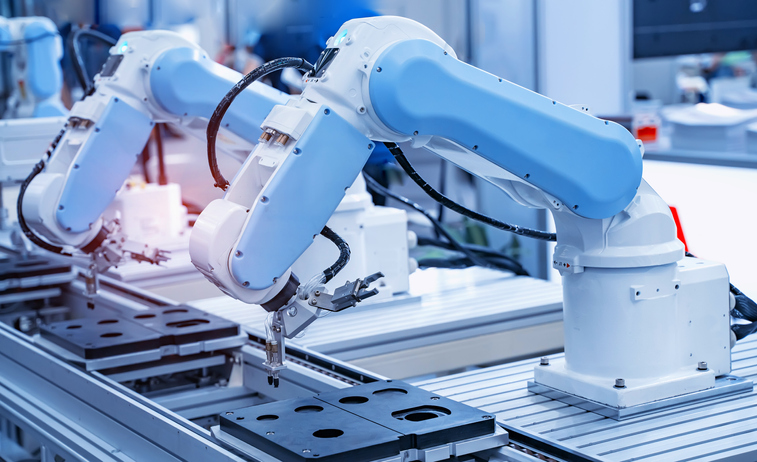

Oct 23The Essential Guide to Polyurethane Processing Machinery

- October 18, 2023

Wide Range of Equipment Impacts Production, Performance

Polyurethane is an incredibly versatile material utilized across various industries from automotive and aerospace to construction and healthcare. To process and manufacture high-quality products, investing in the right polyurethane processing machinery is crucial.

Read more

01

Aug 23Read more

29

Mar 23Applications for Automotive Polyurethane Foams

- March 29, 2023

Automotive Polyurethane Foams Have Countless Capabilities

Automotive polyurethane foams have been used for several decades throughout the automotive industry, and they continue to be crucial materials for various applications. These foams are known for their excellent insulation, cushioning, and acoustic properties, making them ideal for use in a wide range of automotive components. Here, we’ll take a closer look at these foams and their uses within the industry.

Read more

03

Feb 23What Industrial Products are Made Possible with Polyurethane?

- February 3, 2023

Industrial Polyurethane Products are All Around Us

Polyurethane is an extremely adaptable chemical formula, allowing it to be made into various industrial products.

Read more

09

Dec 22Polyurethane: a Multifaceted Chemical Formula

The polyurethane chemical formula is incredibly versatile; it lends itself to the creation of many different products. Polyurethane is flexible, has a high impact and abrasion resistance, strong bonding and electrical insulation properties, and is a relatively inexpensive material when compared to thermoplastics.

Read more

07

Nov 22How is Aerospace Foam Applied?

- November 7, 2022

Aerospace Foam: An Important Part of Aircraft Safety

There is no room for error in the aerospace industry, even when it comes to aerospace foam. This material is found in various areas of an aircraft, including flight deck pads, passenger cabin walls, ceilings, storage containers, class and section dividers, and elements of the lavatory.

Read more

07

Oct 22Polyurethane Machines Spotlight: Spray Equipment Supports Accurate Application for Various Industries

- October 7, 2022

Increase Efficiency in Your Operation with Quality Spray Equipment

Polyurethane machines include spray equipment uniquely positioned to provide accurate application for spray insulation, coatings, and elastomers for various industries. As the insulated foam is a critical component in the military, aerospace, automotive, sporting goods, and consumer appliance sectors, among others, there is a constant need for efficient spray equipment.

Read more

- 1

- 2