You Already Know What Your Polyurethane Pumps Can Achieve

When you made the decision to invest in a particular polyurethane pump, you knew what it would be capable of and how it would benefit your production. Over time, you and your team came to realize those benefits. But as time wore on, and the wear on your pumps did as well, their performance and condition likely began to take a dip. Perhaps material was getting stuck, or perhaps corrosion or other negative effects became more apparent.

At this point, support for your polyurethane pump is needed. But the type of pump you have will likely determine which route you take. For example, two of the most common polyurethane pumps are made by Rexroth and RHL. Rexroth pumps are a more sizable upfront investment — one that you don’t want to have to make again. And while RHL pumps deliver similar performance, they are not as costly and are easier to replace. However, you may not simply have the time or resources to replace a pump. In this case, rebuilding or repairing the pump is needed.

Regardless of the brand, if you’re looking into options for bringing your polyurethane pump back up to peak performance, it’s important to look for a provider that can help you achieve your goals quickly and properly — particularly if you’re operating in the U.S. Let’s explore what to look for in a partner that can bring more to the table than repair and rebuild capability alone.

3 Must-Haves for a Polyurethane Pump Repair/Rebuild Partner

1. U.S.-Based Supply

For companies operating in the United States, having a polyurethane pump repair/rebuild partner that you can rely on within the country is ideal. Rexroth and RHL polyurethane pumps are manufactured in Europe, so leaning on international sources for repair and support not only adds significant lead time to shipments but also increases the cost of the project. By having a U.S.-based partner, you benefit from shorter lead times, lower shipping costs, and faster pump replacements. Perhaps most important, however, is that you won’t be losing production by the hour waiting for your pump to return from its overseas service.

The Linden Polyurethane Difference: Our repair facility is located in Northeast Ohio. Shipments typically arrive at our facility in a matter of days or less, which means our expert team is able to get to work right away to ensure you can get back to doing what you do best.

2. In-House Rebuilding Capability

When you ship a polyurethane pump off to a service provider, the assumption is that they’re the ones who’ll be doing the work. In reality, there may be components of the repair or rebuild that they can’t do in-house. If they have to ship your pump out to another service provider, this adds more time and cost to your project, which is already suffering from lost production. By working with a partner that has in-house rebuilding capability, you benefit from faster turnaround times and lower overall repair costs.

The Linden Polyurethane Difference: We employ fully qualified repair technicians that have been factory-trained by Rexroth in pump repair for the rebuilding of chemical metering pumps as well as by Rotary Power for the rebuilding of their chemical metering pumps.

3. Proof of Performance

If you work with a far-off partner, whose capabilities you’re not even entirely confident in, you not only suffer from extensive repair times and higher costs, but you also won’t be confident in the finished product. If your polyurethane pump were to return to your facility, only for you to find out that it wasn’t properly rebuilt or repaired in the first place, the overall loss would be significantly greater. The process would have to start all over again, and lost production would continue to mount. What’s needed here is a partner that’s not only adept in rebuilding your polyurethane pump but also able to guarantee its performance after the process is done.

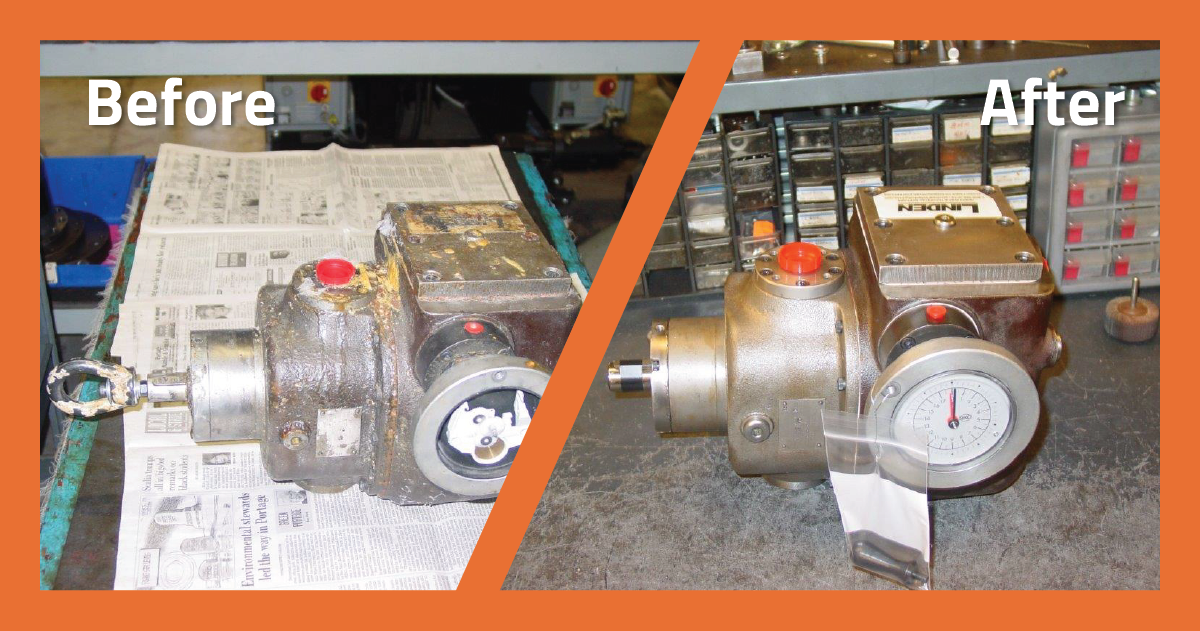

The Linden Polyurethane Difference: When you ship your polyurethane pump to us for rebuilding or repair, we conduct inert flushing and computerized testing prior to sending it back to you. This eliminates any uncertainties and ensures the break-in of the internal components. Flow and pressure performance are verified on a computerized test stand to ensure proper performance in the field.

Experience the Linden Polyurethane Difference

For nearly 40 years, Linden Polyurethane — formerly Linden Industries — has been helping companies throughout the U.S. and around the world not only build best-in-class polyurethane processing equipment but also get industry-leading repair and support for that equipment. Whether you’re looking to have your polyurethane pump rebuilt or repaired, we’ve developed an efficient process that ensures your equipment is returned back to you as quickly as possible and that it operates at peak performance for years to come.

Our new Zip-It & Ship-It program provides you with everything you need to secure and ship your polyurethane pump into our facility for service. If you’d like to speak with our team about your polyurethane pump rebuild or repair needs, please don’t hesitate to contact us.