Keep Running with Repair, Rebuild, and Replacement Services

With the titanic size of the market, it makes sense for any polyurethane manufacturer, producer, or fabricator to be aware of and employ polyurethane repair services in order to stay up-to-speed with ever-increasing production demands.

With applications and uses across virtually every industry, polyurethane saw its global market value increase in 2020 despite the worldwide economic issues associated with the pandemic. The global polyurethane market size was estimated at $70.7 billion in 2020 and is expected to grow at a compound annual growth rate of 3.8% through 2028, according to published market research. Increased demand for building insulation in light of sustainability concerns, and heavy use in the automotive and packaging industries, is expected to drive demand over the forecast period.

It’s clear that polyurethane production tools will remain a necessary component for many companies moving forward. Once invested in polyurethane pumps, mix heads, bulk storage, or metering or blending systems, you’ve come to realize the capabilities and benefits provided by that equipment. You can avoid having to double up those investments with polyurethane repair services, which can extend the life of critical equipment at fractions of the original investment cost.

If you’re looking for options for returning your polyurethane production elements back to peak performance and efficiency, you’ll want to seek out a provider that helps you achieve your goals quickly and properly with the support to ensure those investments are protected for years to come.

Let’s take a look at three important elements of polyurethane processing — pumps, mix heads, and systems — and examine how Linden Polyurethane displays uncommon capabilities in servicing those aspects.

Pump Repair/Rebuild

When looking to service your polyurethane pumps, it’s important to remember three key facets. First, you’ll want a U.S.-based partner to enable quicker pump replacements, lower shipping costs, and shorter lead times. Second, you’ll want a service provider that has its own in-house rebuilding capacity to again lower repair/replacement costs and minimize the potential downtime in your production. Lastly, you should expect proof of performance; your production plan is already disrupted for the necessary repairs, the last thing you want is another delay when the supposedly repaired pump doesn’t operate correctly upon its return. Linden Polyurethane checks all the boxes with its comprehensive pump repair program.

Our repair facility is located in Northeast Ohio, and shipments across the country typically arrive in a matter of days — or less. Our team of fully qualified repair technicians has been factory-trained by Rexroth in pump repair for the rebuilding of chemical metering pumps, and by Rotary Power for the rebuilding of chemical metering pumps. Once the work is complete, we’ll conduct inert flushing and computerized testing prior to its return to you. Flow and pressure performance are verified to ensure proper performance in the field, and the process also eliminates any uncertainties and breaks in the internal components.

The Linden Polyurethane Difference: If you don’t have the time to wait for a complete pump repair or rebuild, we have a pump exchange program to let you address immediate production concerns.

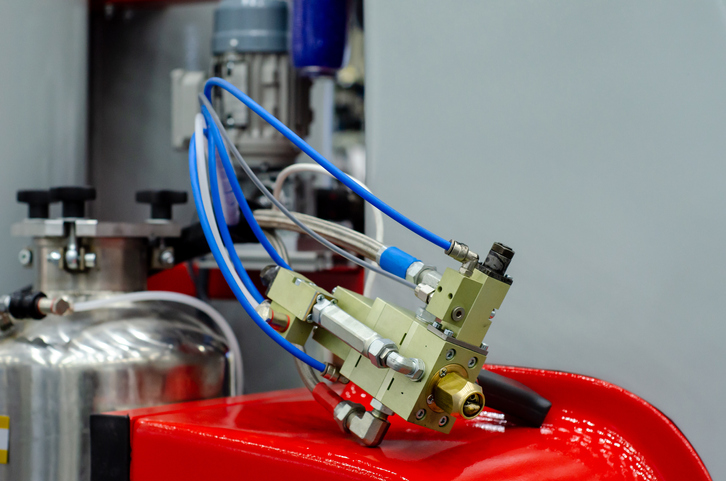

Mix Head Repair/Rebuild

Without a functioning and efficient mix head, in which different materials are brought together to form the material to be applied to the end product, your polyurethane production process can grind to a stop. Responsive mix head repair options and preventive maintenance will help keep your processes running smoothly.

Linden Polyurethane can also support your mix head repair and replacement needs even if we weren’t the manufacturer of your equipment. We can provide repair services to many brands including (but not limited to):

- EMB

- Krauss-Maffei

- Hennecke

- Graco

- Konal

- Decker

- Cannon

- DUT

Leaky mix heads, or those that aren’t dispensing material correctly, require immediate action. Linden can repair your mix head at our facility, or send replacement parts to you directly. As a leader in mix head repair services, we understand the necessity of getting this vital part of your production chain back in action quickly.

The Linden Polyurethane Difference: If you’d like to evaluate one of our mix heads before purchase, or need one while yours is being repaired, we can arrange short-term loans — for a span of weeks or months — to make sure you don’t miss a beat.

Polyurethane System Repairs

Pumps and mix heads may be important elements of your polyurethane processing environment, but they are far from the only elements. Linden Polyurethane provides repair services and other solutions for our whole range of polyurethane foam systems, including metering systems, bulk storage, or bulk blending systems.

If you need to relocate your processing capabilities — due to a new building, expansion, or the transfer of operations — our team can support you through the process to help maintain your production. We can evaluate a new facility to determine what changes or improvements can be implemented. We can also assist in relocating your polyurethane systems from one facility to another. We’ll make sure you’re ready for operation when the transition is complete.

Our refurbishing services help your polyurethane foam systems revert to their original condition. More than simple repairs, refurbishing will bring your systems back to their brand-new production and efficiency levels. In addition, we’ll develop a timeline and plan to implement the refurbishment with an eye on improving your production capabilities.

The Linden Polyurethane Difference: If all you need is a replacement for a damaged or broken part, or a replacement component ready to go to maintain production, our extensive inventory of spare parts can quickly meet your needs.

Lean on Linden Polyurethane for Unparalleled Support

For nearly 40 years, Linden Polyurethane has been helping companies throughout the U.S. and around the world not only develop best-in-class polyurethane processing equipment but also rely on industry-leading repair and support for that equipment. Whether you need to relocate bulk storage solutions, simply need replacement parts for critical mix head elements, or repair essential polyurethane pumps for your processing facility, we’ve developed a complete polyurethane repair service package that will minimize disruption and get your equipment back online quickly.

For example, our Zip-It & Ship-It program provides everything you need to quickly and efficiently ship important components, like mix heads and pumps, to our facility for service.

Contact us today to speak with our team about your polyurethane repair needs.