16

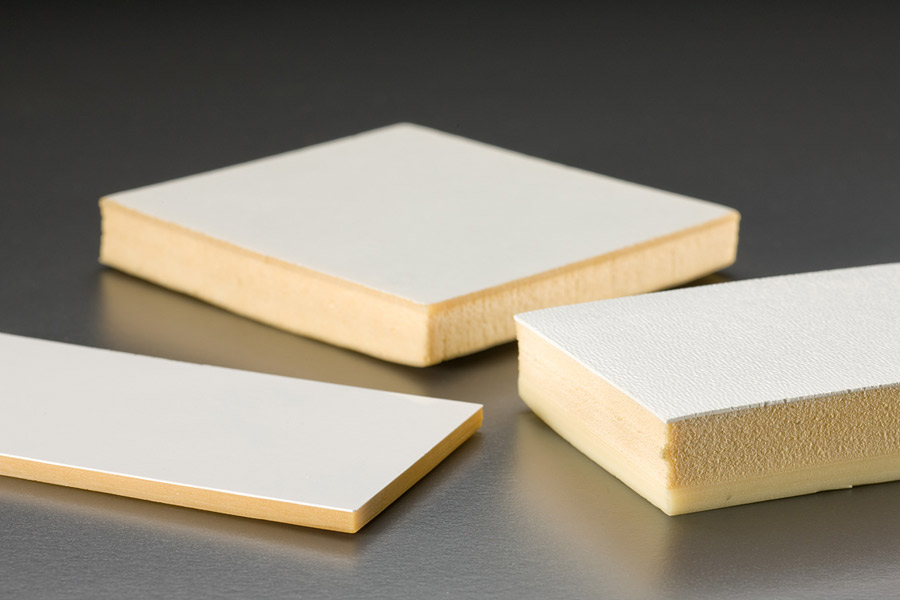

Apr 20High Strength Foam: 3 Keys to Successful Results

- April 16, 2020

Just About Every Industry Needs High Strength Foam

High strength foam is a core component of numerous industries throughout the world, and for good reason. This type of polyurethane foam is extremely rigid and capable of withstanding abuse in many forms. These include extreme and often rapid temperature variations, sudden impacts and long-term wear, and moisture.

16

Mar 20How Bulk Polyurethane Can Help Grow Your Business

- March 16, 2020

Looking for Cost Efficiency? It’s Time to Consider Bulk Polyurethane

Over the past several years, the polyurethane market has risen consistently in value by around 5 percent annually. The reason for this is due to the benefits of polyurethane itself. As an incredibly lightweight yet durable material, polyurethane is high in demand in numerous industries and markets. Its affordability compared to other more costly materials also makes it a strategic solution for companies looking to maximize margins on their production. But despite these advantages, it’s becoming more and more important to invest in bulk polyurethane.

18

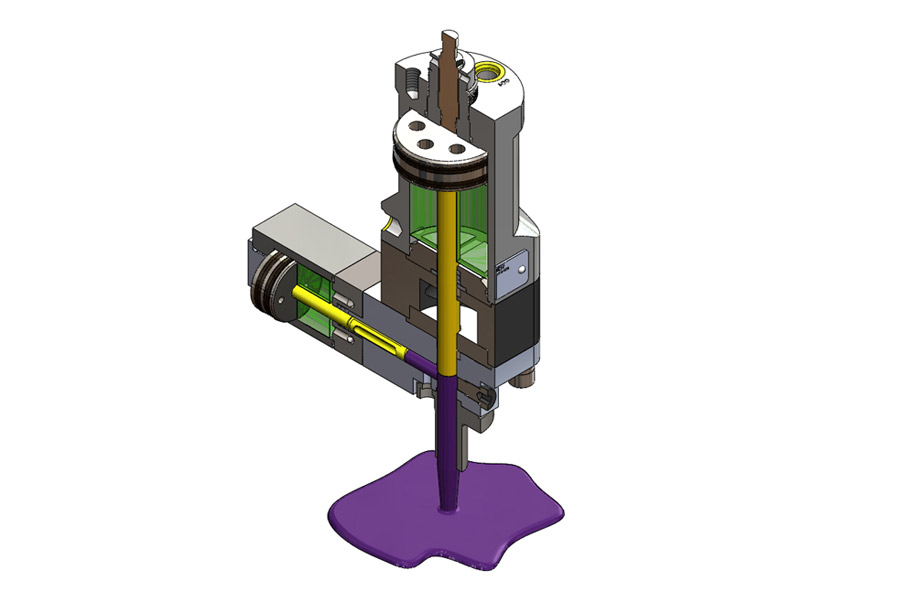

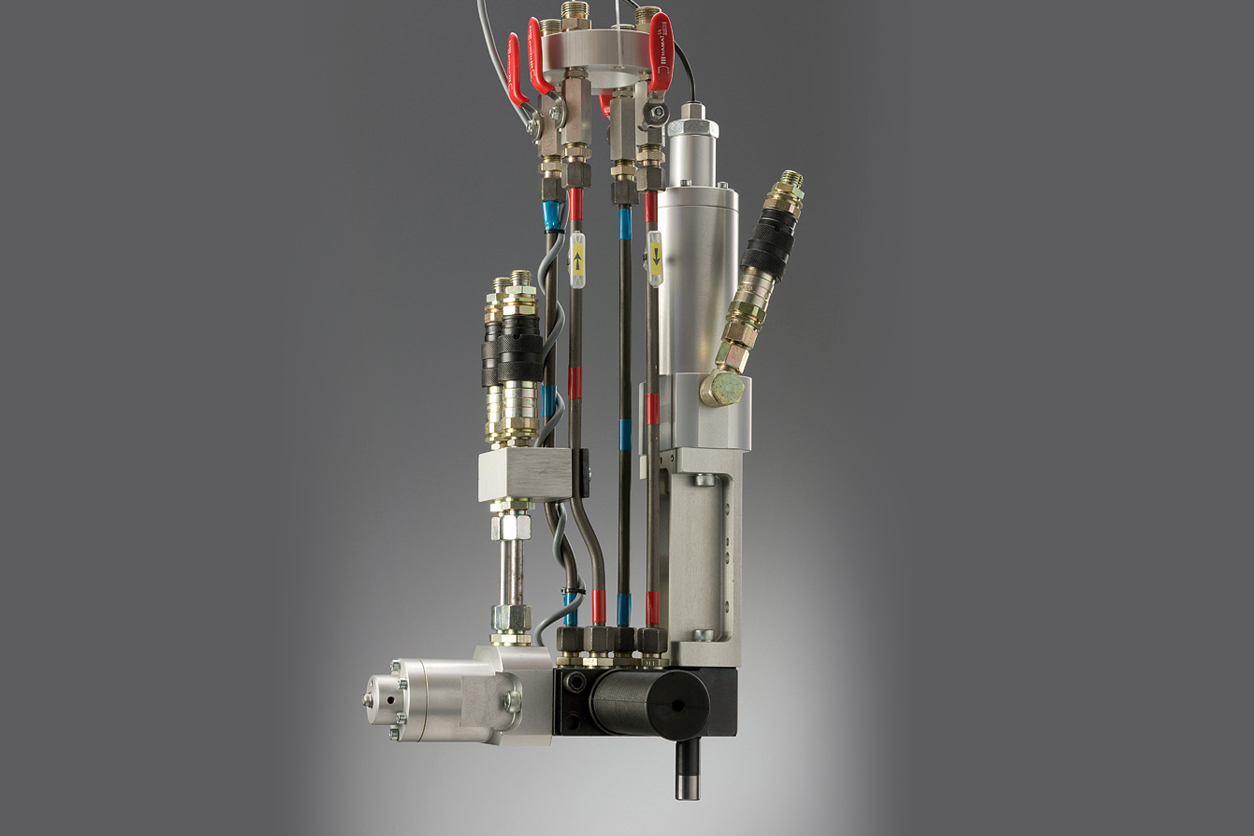

Feb 20Chemical Metering Systems: The Production Control Center

- February 18, 2020

What Are Chemical Metering Systems?

Whether your organization is in the aerospace, automotive, medical, or sporting goods industry, everything that occurs in your production environment is controlled and regulated in some way. When it comes to polyurethane processing, much of that control is set and monitored by a chemical metering system. These devices control how much material is distributed from a polyurethane storage system (such as a bulk chemical storage tank) to the mix head, where the material is then sprayed, poured, or otherwise distributed onto a specific surface. Chemical metering systems also control key aspects of polyurethane mixing ratios.Read more

16

Jan 20Why Invest in Chemical Holding Tanks?

- January 16, 2020

Tired of Those Annoying 55-Gallon Drums and Totes? Go with Chemical Holding Tanks Instead

You’re not alone. For years, companies that manufacture products using polyurethane or that apply polyurethane in other applications have been ordering, hauling, storing, and handling material in 55-gallon drums rather than chemical holding tanks. For companies with more significant production demands, this inefficiency was upsized into significantly larger 270-gallon totes. Depending on overall production volume, companies might have anywhere from dozens to hundreds or even thousands of these drums in their facilities throughout their footprint.

16

Dec 19The Key to Mixing Polyurethane: Precision and Consistency

- December 16, 2019

A Material for Every Market

Polyurethane is one of the most customizable materials available in markets today. Whereas other materials allow for significant customization for appearance purposes only, polyurethane can acquire a number of different properties. By mixing polyol and isocyanate in specific ratios and combining it with other chemicals, companies can achieve remarkable results.Read more

08

Nov 19The Importance of Efficient Mix Head Repair

- November 8, 2019

Production Success Requires a Properly Functioning Mix Head

Numerous Industries around the world rely on their mix heads for efficient, ongoing production. Many products and materials require polyurethane as a key ingredient in their design and construction. Read more

22

Oct 19Improve Polyurethane Foam Cell Structure with Gas Nucleation

- October 22, 2019

Why Polyurethane Foam Cell Structure Matters

Polyurethane foam cell structure is critical to multiple industries for countless products that consumers and businesses use each and every day. Many of these products are part of our daily activities, but just as many — if not more — go unseen. That’s because they serve as a structural, protective, or other foundational element of those products.

15

Oct 194 Ways That Bulk Chemical Storage Tanks Improve Productivity

- October 15, 2019

First, What Are Bulk Chemical Storage Tanks?

Bulk chemical storage tanks are far more than just a container for large volumes of polyol and iso. It’s a complete material storage system designed to make your organization’s production facility more streamlined, efficient, sustainable, and cost-effective.

08

Oct 19Welcome to the New Linden Polyurethane Website

- October 8, 2019

Why We Built a New Website

Welcome! As an organization with more than 30 years as a leading partner in the global polyurethane industry and the only U.S.-based polyurethane processing equipment manufacturer, we decided that it was time to upgrade the Linden Polyurethane website to properly reflect our growth and capabilities.